Tom Marsh, who founded Overland Models, was from Muncie, Indiana and grew up around the Nickel Plate. Although Overland imported models in HO and N, Tom was an O Scaler and had a special affinity for models in our scale. And although Tom’s fascination with big Union Pacific models was whetted by an Air Force tour out west, he also had a huge affection for Nickel Plate.

In working with Ajin Models of Korea in the mid-1980s, Overland imported several O Scale models of Nickel Plate equipment. These included 1000 series standard wooden cabooses, 400 series bay window cabooses, and Alco PA’s. The PA’s came in different variations, but included at least 10 with NKP-specific details.

In 1984, Overland also imported 150 Ajin-built models of the Nickel Plate S-2 berkshire locomotives. The S-2 (730-769) is generally the best regarded class of all of the Nickel Plate Berks. All of the restored fantrip engines and all but one (S-3 779) of the preserved engines are S-2s.

The Overland S-2s sold out quickly., and are highly sought after. Examples occasionally appear on the secondary market through eBay and at train shows. The large, rectangular, green Overland boxes are a spotting feature.

After 40 years (!), the condition of the models vary. As with any used engine, close examination is necessary so you are aware prior to purchase of any damage, missing parts and repairs which will be necessary. Prices vary widely, based at least in part on the different conditions and on the difficiencies described, below.

The Ajin S-2s were Overland’s first O Scale steam locomotive. While the engines accurately reflect the prototype and the brass detail is beautiful, there are certain important aspects of the Overland engines of which any prospective purchaser needs to be aware.

The first is that the gearbox with which Ajin built the locomotive was comprised of two sheets of sheet brass encasing an open gear set with a 12:1 reduction. There was no excuse for such a primitive gearbox, as KTM had been making sturdy mechanisms and precision gearboxes with an appropriate gear ratios for several decades before the S-2 was designed. The crude gearbox resulted in poor low speed performance and decreased power.

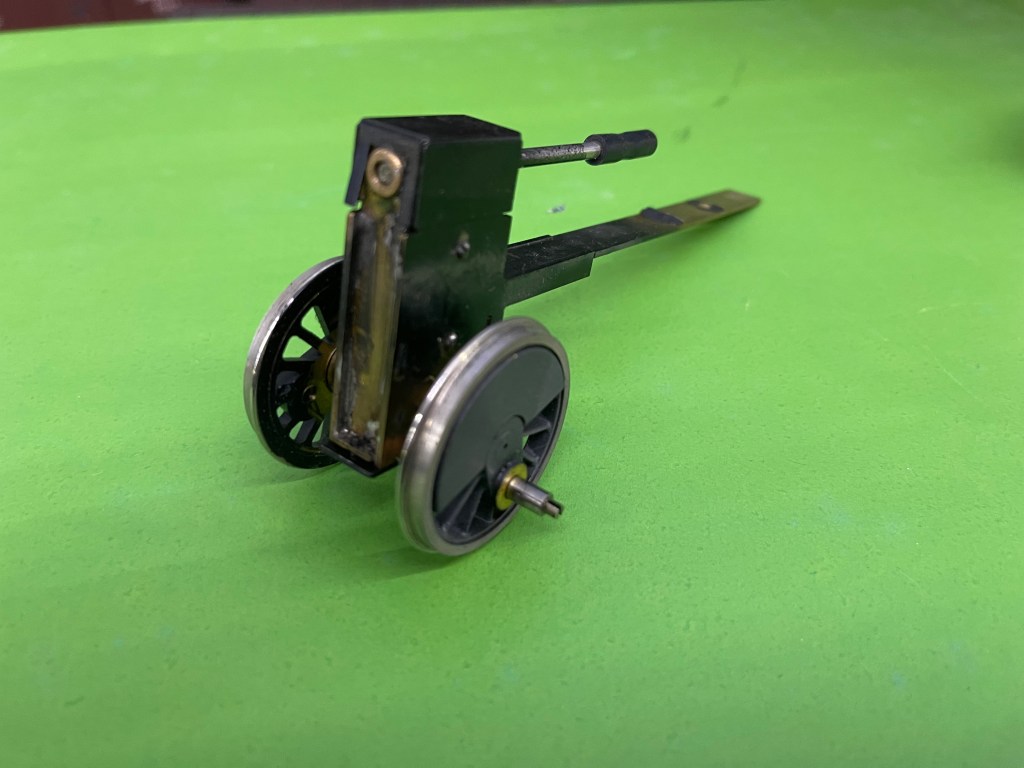

To the credit of Ajin, Overland and Tom Marsh, Ajin produced, imported and sold a separate drop-in replacement gearbox for the S-2. The replacement gearbox closely resembles a KTM gearbox. The factory replacement is large, black, says “Ajin” on the bottom and comes mounted on a geared driver, to be dropped into place, after disconnecting the siderods, which must then be reconnected. But the factory replacement does not require quartering the main driver, an important advantage.

The replacement gearboxes came in a white cardboard box, with green foam on the inside. A printed label on the box describes the contents as a replacement gearbox and main driver. The replacement gearbox/driver combination was fairly common at train shows in the early years, but they are almost never seen now, either in conjunction with S-2s or separately. Ajin also made and sold (probably through Overland) a generic gearbox, without a driver. Those could be used on S-2s, but would require removal of a driver to access the gear and requartering the driver as part of the reassembly. These too were once abundant but are now scarce on the secondary market.

The photos below show the old gearbox from the side and from the bottom. When the engine is turned over, the gearbox is visible in a slot at the bottom of the frame. The old gearbox is flat on the bottom, has no lettering and is secured by two screws in a line.

The performance deficiencies in the NKP S-2 caused by the gearbox can be somewhat alleviated – although not cured – by installing a more powerful motor. I suggest Pittman/PennMotion No. 9433, which is the same shape as the factory-installed motor and is easy to install.

The Pittman 9433 motor is a replacement for the factory-installed motor. Substitution of the 9433 provides some improvement in operation if used with the old, as-built 12:1 gear box.” The motor on the right is a 9433 equipped with a flywheel (custom turned; drawings available on request) and mounted on a bracket, which provides stability and improves operation.

The second major issue in the Overland S-2 Berkshire is the frame. Most brass engines have brass frames, either fabricated from brass side sheets and soldered or screwed together with spacers between, or milled from solid stock. The frames have openings for the insertion of the driver bearings.

The milled brass frames are a drop-in substitute for the Zamac frames. Save the frame to salvage the screws and driver bearing keeper plates for installation on the new frame.

The alignment of the bearing slots is important; if the slots are uneven or not straight, the resulting variations in distances between drivers as they rotate will cause uneven resistance and negatively impact performance.

For reasons unknown, Ajin fabricated the frames for the S-2s from cast Zamac, an alloy of zinc, aluminum and copper. For model railroad applications at least, Zamac is the alloy from hell. It has a history of crumbling and cracking. Interestingly, that deterioration has not been a problem with the S-2 frames. However, the S-2 frame casting – with a solid top but open slots on the bottom for the drivers – warped. The warping does not appear to have been consistent from casting to casting; and the distortions in some frames are minimal. But the casting defects basically mean that the distance between the drivers may have excess space in the bearing slots and/or the drivers are are not consistent through their full rotation, resulting in jerky performance.

Resist the temptation to correct warping by straightening the frame. Zamac is not a malliable metal; and whether the effort to straighten the fame is slow – as in placing the Zamac frame in a vice and tightening it – or fast – as in hitting the Zamac frame with a hammer – the result will be the same: the Zamac frame will break. Realligning a broken frame is to preserve or improve the spacing is somewhere between extremely difficult and impossible.

The issue of the warped frame and its adverse impact on performance was spotted by John Eichman, a former Nickel Plate employee and accomplished P-48 modeler. He found a way to correct the impact of the warped frames on performance by carefully measuring the frame openings and by using his educated hands to roll the installed drivers without and then with siderods to identify spacing problems. He then inserted shim brass of required thicknesses to equalize the distances between the bearing slots and reduce any slop between the slots and the bearings, the differences in distances between drivers can be reduced, with corresponding improvement in performance. This is a multi-step, laborious and uncertain process, which might be described in more detail at a later time. But it can be done.

John Eichman also worked with his friend and fellow P-48 modeler Carl Jackson to prepare a drawing of the S-2 frame. Carl’s drawing included not only the frame dimensions but the locations of holes to be drilled and tapped. The spacing deficiencies could be cured by milling the frame from brass bar stock. A CNC milling machine loaded with the program based on Carl’s drawing is ideal; and once the program is installed, the milling process is essentially automatic. The result is a beautiful frame, no warping, identical distances between drivers and no variations in distances through driver rotations.

Tom Marsh shepharded the process of having 25 milled brass replacement frames produced in Korea. They were delivered – and promptly sold out and disappeared. The frames were not well-publicized, and more than a few modelers who would have wanted them were frustrated when they came and went without their knowledge.

In response to recent requests, David Vaughn used Carl Jackson’s drawings, with Carl’s permission, to have 14 more frames milled. They arrived in the spring of 2025. The frames are gorgeous, indistinguishable from the Korea-produced replacements. Five frames from the rerun remain available as of June 30. See the detail parts section of this Website for price and availability.

Note that the replacement frames are tapped for the different metric screws and bearing retainer plates from the original. Keep the existing frames, bearing retainer plates and screws until parts are transferred and installation is complete.

There are undoubtedly more inside stories about the Overland S-2s. O Scale Central (OscaleCentral.com) sponsors a monthly online program, using the Zoom platform, to bring O Scale 2 Rail news and features to the OS2R community. In OSC’s August 2025 program, Overland founder Tom Marsh will be a guest of the program and will share the story of Overland Models. Questions about the NKP S-2 will almost certainly come up. Tune in.

A stock Overland S-2 accurately captures the feel and proportions of the prototype S-2. Nickel Plate 48’s Berkshire Backshop Section includes detail parts to upgrade the Overland engine.

Readers may address questions and comments about this article by responding below in the comments or by emailing David Vaughn at (nkpos2r@gmail.com). Comments will be edited and posted. Additional material from Tom Marsh or from readers will be edited and presented.

Leave a comment